-

Back

-

Categories

-

- Daydeal!

- Blog

- Faq

-

In this article I describe how we made a wooden LEGO doll.

General description

Actually, the idea of making a wooden Lego doll came about because I saw examples of it elsewhere on the internet. I also wanted to be able to do this and immediately have a detailed version in which at least the arms and legs can move as with real Lego. The final design is 28 cm high, 17 cm wide and 6.5 cm thick.

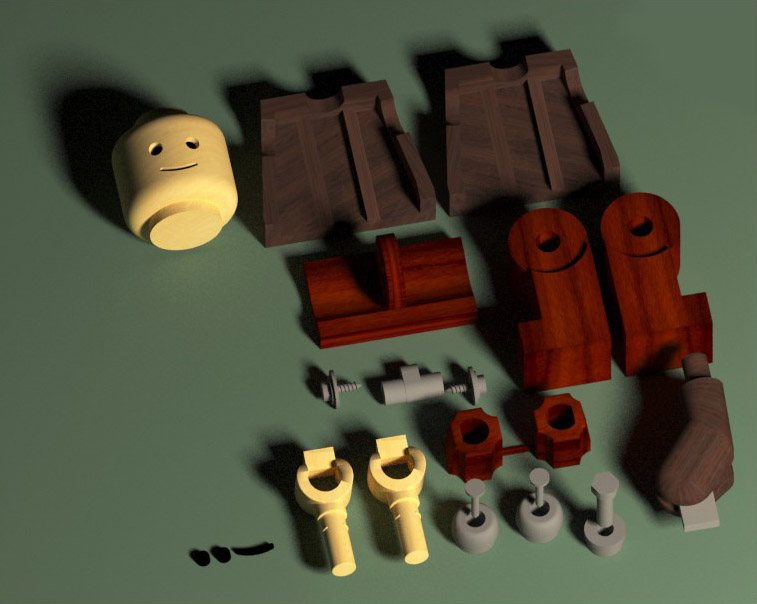

The parts

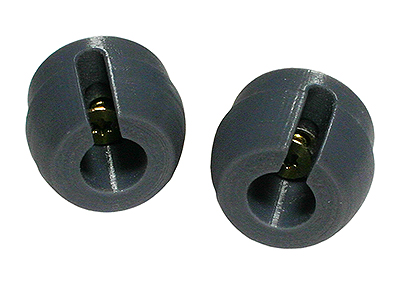

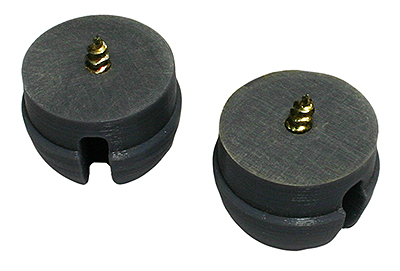

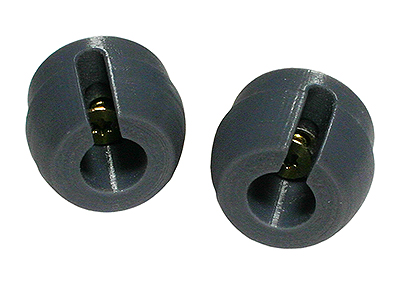

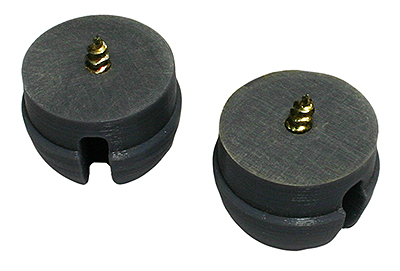

The whole consists of different parts, designed in Autodesk 3D Studio Max. The 3d (STL) files were then used to actually mill and 3d print the parts from wood. There are a number of parts that do not consist of wood, the hinge points for the arms, legs and the connection with the neck. We chose to make these parts from plastic because it seemed better to me to maintain the 'skidness' of these parts.

Linden wood was used for the head and hands, for the body and arms the original idea was to use paduk and for the legs american walnut from the Arnhemse Fijnhouthandel (www.af.nl) but due to a mistake we turned it around. The legs are made of padouk and the body and arms of American walnut. The mouth and eyes are inlaid with a few bits of ebony, expensive wood, but in such a small amount it's not a big deal. Speaking of costs, or rather time: for people who want to copy this doll: count on quite a few hours, even using the stl/dpj files offered here. The whole thing took me about 60 hours, but this does include the design of the 3d files.

Software

As mentioned, we used 3D Studio Max for the design. In addition, Deskproto V6 was used for the milling and Cura 15 for 3d printing. The 3d printing was done on an Ultimaker without a heated bed in PLA. The milling was done on an ICP 4030 from Isel Gmbh. A 4th axis is used in the milling machine for milling the head, arms and hands.

Post-processing, assembly and end result

All the wood is finished with Danish oil after it has been sanded with sandpaper. There have been quite a few setbacks, broken cutters, glue residues, discolorations (for example, the head has become a lot darker than intended) and the worst thing is that the arms do not turn as easily as planned. One of the arms also has a crack. But all in all a successful result.

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

| |

| |

| |

| |

| |

To make a version of the wooden legoman yourself: | |

Deskproto.com published an article about our project at http://www.deskproto.com/gallery/legodoll.php

In this article I describe how we made a wooden LEGO doll.

General description

Actually, the idea of making a wooden Lego doll came about because I saw examples of it elsewhere on the internet. I also wanted to be able to do this and immediately have a detailed version in which at least the arms and legs can move as with real Lego. The final design is 28 cm high, 17 cm wide and 6.5 cm thick.

The parts

The whole consists of different parts, designed in Autodesk 3D Studio Max. The 3d (STL) files were then used to actually mill and 3d print the parts from wood. There are a number of parts that do not consist of wood, the hinge points for the arms, legs and the connection with the neck. We chose to make these parts from plastic because it seemed better to me to maintain the 'skidness' of these parts.

Linden wood was used for the head and hands, for the body and arms the original idea was to use paduk and for the legs american walnut from the Arnhemse Fijnhouthandel (www.af.nl) but due to a mistake we turned it around. The legs are made of padouk and the body and arms of American walnut. The mouth and eyes are inlaid with a few bits of ebony, expensive wood, but in such a small amount it's not a big deal. Speaking of costs, or rather time: for people who want to copy this doll: count on quite a few hours, even using the stl/dpj files offered here. The whole thing took me about 60 hours, but this does include the design of the 3d files.

Software

As mentioned, we used 3D Studio Max for the design. In addition, Deskproto V6 was used for the milling and Cura 15 for 3d printing. The 3d printing was done on an Ultimaker without a heated bed in PLA. The milling was done on an ICP 4030 from Isel Gmbh. A 4th axis is used in the milling machine for milling the head, arms and hands.

Post-processing, assembly and end result

All the wood is finished with Danish oil after it has been sanded with sandpaper. There have been quite a few setbacks, broken cutters, glue residues, discolorations (for example, the head has become a lot darker than intended) and the worst thing is that the arms do not turn as easily as planned. One of the arms also has a crack. But all in all a successful result.

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

| |

| |

| |

| |

| |

To make a version of the wooden legoman yourself: | |

Deskproto.com published an article about our project at http://www.deskproto.com/gallery/legodoll.php