Information

Subcategories

-

<p>Here you will find our extensive collection of micro drills, packed in a transparent, plastic box. We have boxes with 10 pieces only of 1 diameter (for example 0.8 mm) as well as combi sets (for example 0.4 - 1.0 mm). The shaft of the drills in these sets is always 3.175 mm and they are always provided with a spacer (ring) in a random color.</p>

-

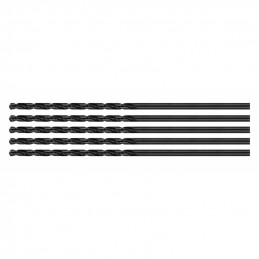

<p>Standard drills are about ten centimeters long, but sometimes that's just not long enough. For example, when making garden constructions, such as berceaus, pergolas, garden furniture or verandas, where strong connections are required, it is important that holes are drilled right through wooden beams, which is not possible with standard length wood drills. Then you need the <strong>extra long wood drills</strong> from our assortment. ##</p> <h2>Extra long wood drills in our assortment</h2> <p>On this page you will find various extra long wood drills. These wood drills have a length of 300 mm, which is almost three times longer than normal wood drills, especially for the professional and the experienced handyman who does a lot of work with wood.<br /><br />Our range contains extra long wood drills with different diameters , ranging from four millimeters to twelve millimeters. Or are you looking for extra long wood drills with different diameters? You will also find these in our range.</p> <h2>Extra long wood drill bits for wooden constructions</h2> <p>Admittedly, in most cases a standard length drill is sufficient. Certainly with wood drilling, the best-known application is the pre-drilling of holes, to make it easier to screw into the wood. But for handymen who spend a lot of time in the garden, a wood drill with such a standard length is often not enough. After all, garden furniture and other garden constructions are usually more robustly constructed than indoor furniture, to withstand our climate and to prevent them from hitting the ground with every gust of wind.<br /><br />One of the examples where an extra-long wood drill works well. comes in handy is assembling a garden table made of sturdy, sawn planks. Often the legs of such a garden table are placed crosswise against each other and a threaded end comes right through the legs. To do this, you must first drill a hole through both legs. Then you put the threaded end through it and finally you ensure a connection that can withstand a knock with bolts on both sides.<br /><br />It is also customary when attaching the planks for the table or for the seating planks. drilling through the planks and inserting a bolt through the hole from above and tightening it from below with a nut.<br /><br />In short, extra long wood drills are indispensable for garden handymen and wood professionals.</p>

-

<p>Contrary to what the name suggests, you can use HSS metal drills not only to drill holes in metal, but also in wood and plastics. They are real all-rounders that can be used for various applications. As a handyman, you only need one set of drills. So if you sometimes drill in wood, sometimes in metal and sometimes in plastic, these HSS metal drills are the right choice. ##</p> <h2>How do you recognize HSS metal drills?</h2> <p>A metal drill is characterized by the sharp point and the equal diameter over the entire length of the drill. The drill point with this type of drill is usually sharpened with an angle of 118 degrees. Thanks to this drill angle you can be sure of a good removal of metal scraps while, on the other hand, the drill is still easy to place.</p> <h2>Frictional heat</h2> <p>The abbreviation HSS that you often hear in combination with metal drills, stands for High Speed Steel. This indicates that these drills function best at high speeds. This high number of revolutions creates friction with the metal, which can cause the metal and the drill itself to glow red. That is usually not a problem, HSS metal drills are made for that and in general it will not reduce the drilling performance. Nevertheless, it is often recommended to cool the drill and the metal with drilling oil with these metal drills. The use of drilling oil has the advantage that the frictional heat decreases as a result. This is especially nice when drilling in stainless steel (stainless steel), because this material actually becomes harder when the temperature increases. One of the problems with drilling in metal is that it is often difficult to keep the drill tip stable where the hole is to be drilled. For the best drilling result, without all kinds of annoying scratches, you can first make a small hole in the metal with a punch, center punch or with a simple nail. If you want to make a large diameter hole, it may be best to drill a much smaller diameter hole first to allow for stable positioning of the drill.</p> <h2>Different diameters extra long HSS metal drills</h2> <p>In our range you will find metal drills with different diameters that are supplied per set. Some sets consist of metal drill bits of the same length and diameter, while other sets consist of metal drill bits with varying diameters. So whatever you are looking for, you will certainly succeed here.</p>

-

<p>High-speed steel (HSS) metal drill bits are a type of drill bit that is commonly used to drill holes in metal. HSS drill bits are made of a type of hardened steel that is able to withstand the high temperatures and pressures that are generated when drilling through metal. This allows the drill bit to maintain its sharpness and cutting ability for longer periods of time compared to other types of drill bits. HSS drill bits are available in a variety of sizes and shapes to suit different drilling applications, and are commonly used in a wide range of industries, including construction, automotive, and manufacturing.</p>

-

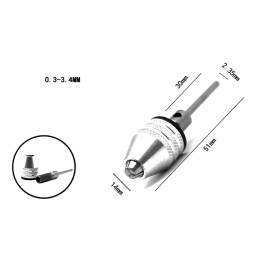

<p>Drilling machines and cordless drills are indispensable for jobs in and around the house. Whether it concerns hanging a painting or family photo, assembling a cupboard or building a (garden) house, without a drilling machine it will be a difficult job, but just a drilling machine and a set of drills is not enough for these jobs. To be able to use your drill in all situations, you need a number of accessories, such as the drill accessories below.##</p> <h2>Useful drilling accessories: depth rings</h2> <p>Depths are mainly used when drilling in relatively thin walls. With these rings on your drill you can easily and precisely indicate how deep you want to drill. How does it work? Very simple, you turn a ring on your drill and you drill so deep until the ring touches the wall and then you stop. With this relatively simple drilling aid you prevent that you drill too deep or that you do not drill deep enough.</p> <h2>Center points or dowels for an optimal drilling result</h2> <p>Another useful tool for drilling is our center points or dowels. You use this to make a hole in the substrate in which to drill, such as wood, metal and stone. By placing the drill tip in this well, you will reduce the chance of your drill slipping while drilling. You are assured of an optimal drilling result, especially if you use a center point with approximately the same size as the drill point.</p> <h2>Drilling around a corner</h2> <p>Drilling around a corner? It is a joke often heard among handymen and professional builders. It sounds like a fairy tale, but it really is possible with the angle attachment from our range of drilling accessories. Thanks to an ingenious design, you can actually drill around a corner. Extremely useful if you have limited space.</p> <h2>Many more drilling accessories</h2> <p>In our range of drilling accessories you will also find the indispensable chuck keys for quickly changing a used drill or bit. Of course, chuck keys are included with the drills themselves, but it is easy to lose them, especially on more extensive jobs, where several handymen bring their own drills.</p>

-

<p>Auger drill bits, sometimes called snake drill bits, are a type of drill bit that is designed to create holes in wood. They are called "snake" drill bits because they have a screw-like appearance and can be used to drill long, curved, or angled holes.</p>

-

<p>A <strong>concrete drill</strong> is used to drill holes in materials such as stone, masonry and concrete. Traditional drills are too fragile for this purpose. <strong>Concrete drills</strong> are made of durable, harder material that can withstand the force. These drills are usually equipped with an SDS(plus) system. An ordinary drill is fixed by the chuck of a drilling machine, a drill with an SDS(plus) shaft has a recess on both sides through which it is clicked into the drill, which can only be done in 1 way. The drill is immediately secured. This way it will not move during drilling. The concrete drills we sell are available in diameters 6 to 25 mm with lengths of 110 to 400 mm.<br />##</p> <h2>How to drill into concrete with a impact drill</h2> <p>There are several steps to follow when drilling into concrete. These are:</p> <p><strong>Marking the spot<br /></strong>You should start by marking the location where you are going to drill a hole. In addition, you need to think about how deep the hole should be. You can measure this with the help of a stop bar. You can also determine the depth by wrapping masking tape around the drill.</p> <p><strong>Prepare the drill<br /></strong>Wear your safety glasses. Next, you need to insert the right size concrete drill into your impact drill. Make sure it is properly locked to prevent slipping while drilling.</p> <p><strong>Put yourself in the right position<br /></strong>Hold the drill firmly and place your feet shoulder-width apart. To get more control, you can use the extra handle. If there is no extra handle, you should hold the hammer drill in the same way as a handgun. Care should be taken to keep the drill perpendicular to the concrete. The hammer action will cause some recoil.</p> <p><strong>Drill a guide hole<br /></strong>When the drill is on a slower setting, make the guide hole. If the drill has only one speed, you can use it in short bursts until the guide hole is about 1 cm deep.</p> <p><strong>Drill the desired hole<br /></strong>Hold the drill firmly but lightly. This will allow you to tackle any rock piles or hard material in the concrete. It is easy to lose control of the drill when drilling through concrete. With the guide hole in place, you can easily control the drill. As you become more and more confident, you can now increase the rotation speed until you have made the complete hole.</p> <p><strong>Remove debris/grit<br /></strong>It is advisable to pull the drill back after every 10 seconds to remove the debris from the hole. This will allow the drill to continue working on the hard concrete without being bothered by the grit.</p>

-

<p>Our battery-powered drills are ideal for small jobs in and around the house. Small and handy, so you can easily take them with you in the handy plastic case. You can choose the drill that is equipped with an extensive set of accessories or you can choose the drill with only a set of bits. The choice is yours. We would know and buy them both. This gives you extra flexibility and allows you to use one while the other is being charged. You can't beat it for the price! You will also find all kinds of other handy devices on this page.##</p> <h2>Drills with battery</h2> <p>Our battery-powered drills are made for drilling in light materials, such as aerated concrete, lighter woods and plastics, but they are also perfect for screwdriving. You can replace the bit in the blink of an eye, so that you can quickly drive in or remove different types of screws. Our tip is to buy at least two of these drills so you can keep working if one needs to be recharged.</p> <h2>Engraving as a hobby</h2> <p>Engraving is a fun hobby. Of course you will achieve the best results with a steady hand, but even without a steady hand you can personalize items such as glasses or cups. With an engraving machine you can turn an apparently simple object into a personalized gift. Of course, like any hobby, engraving takes some practice and some perseverance. So you don't have to give up if it doesn't work the first time. If you keep trying, you will find yourself making rapid progress. Because of the price of our engraving machines, you certainly don't have to leave it: they are extremely competitively priced. Very suitable if you want to try out your engraving skills!</p> <h2>Drills and other multi-tools for beginners and professionals</h2> <p>People often purchase specialized equipment for every type of job. They have a whole shed with drills, miter saws, jigsaws, tile cutters, sanders and much more. In practice, this is not necessary at all, and you can work well with a multi-tool. These devices usually have a power unit and a wide variety of extensions, depending on the job you want to do. Perfect for novice DIYers. This way you save a lot of money, but you also save space in your shed. Multi-tools are not only bought by novice do-it-yourselfers, also professionals who have to perform different operations can choose to use a multi-tool for one or more of these operations. Because some tasks can be done just as well by a multi-tool as by an expensive, specialized piece of equipment.</p>

-

<p>Hand drills are ideal for drilling small holes in soft metals such as aluminum, but they are also perfect for making holes in cork, wood, plastic and rubber. Due to the size of the holes that are made, drilling requires little force and the holes can be made with extreme precision.##</p> <h2>Use hand drills in model building</h2> <p>Model building is a fantastic hobby. Models of airplanes, cars and ships are available in almost every toy store. They can be glued together and then painted to look exactly like the original. But there are many more forms of model building. Think of trains, for example, where enthusiastic hobbyists manage to build hefty dioramas complete with cities, mountains, waterways and of course one or more train stations with an astonishing resemblance by making clever use of wood, cardboard and plaster. Of course including moving trains that prefer to run together in complex schedules. Yet another form of model building is the reconstruction of specific aircraft, cars, ships and equipment on the basis of original construction drawings and photos. From scratch, closely resembling models are made of the original. With each of these forms of model building, a lot of work is done with soft materials and there is a need to make holes in these materials. For example, for the passage of thin electrical wire cables to illuminate objects. When holes have to be drilled in these materials, modellers prefer to use hand drills rather than cordless drills or electric drills, because hand drills provide an optimal feeling and therefore allow very precise work.</p> <h2>Hand drills when making jewelry</h2> <p>But also makers of jewelry are avid users of <strong>hand drills</strong>. After all, precious metals such as gold, silver and platinum do not oxidize, but they are also relatively soft materials in which holes sometimes have to be drilled, for example to be able to connect them together. Hand drills are ideal for this, as they offer maximum control. In addition, by drilling manually, you can very precisely determine the force with which you drill. Not all jewelry is made of precious metals. Especially in the corner of people who make jewelry as a hobby, you will find plenty of fanatic makers of jewelry who use modern plastics, such as epoxy resin. By pouring a colored epoxy resin into a mold and letting it harden, you can make the most beautiful jewelry. You can use this epoxy resin jewelry as a charm in a bracelet, necklace or earrings by making holes in it with a <strong>hand drill</strong>. On this page you will find various excellent hand drills, possibly equipped with the corresponding drills. This way you can go in all directions as a model builder or maker of jewelry.</p>

Drilling

WD1567869185

Price

€20.95

Free shipping!

In stock

WD1567869041

Price

€17.95

Free shipping!

In stock

WD1567868419

Price

€23.95

Free shipping!

In stock

WD1567867559

Price

€18.95

Free shipping!

In stock

WD1567863351

Price

€19.75

Free shipping!

In stock

WD1566169302

Price

€24.95

Free shipping!

In stock

WD1585587027

Price

€24.95

Free shipping!

In stock

WD1568405891

Price

€23.95

Free shipping!

In stock

WD1601228523

Price

€21.95

Free shipping!

In stock

WD1717680707

Price

€5.95

In stock

In stock

WD1743166589

Price

€11.95

In stock

In stock

WD1567875238

Price

€11.95

In stock

In stock

WD1566513151

Price

€23.95

Free shipping!

In stock

WD1575897288

Price

€14.95

In stock

In stock

WD1573390045

Price

€2.95

In stock

In stock

WD1757942607

Price

€89.95

Free shipping!

In stock

WD1757942511

Price

€74.95

Free shipping!

In stock

WD1757942363

Price

€64.95

Free shipping!

In stock

WD1757942023

Price

€57.95

Free shipping!

In stock

WD1757935132

Price

€49.95

Free shipping!

In stock

WD1757934802

Price

€37.95

Free shipping!

In stock

WD1757934448

Price

€26.95

Free shipping!

In stock

WD1753617700

Price

€29.95

Free shipping!

In stock

WD1745772590

Price

€14.95

In stock

In stock

WD1745772442

Price

€13.95

In stock

In stock

WD1745772158

Price

€12.95

In stock

In stock

WD1745771897

Price

€12.95

In stock

In stock

WD1745771535

Price

€12.95

In stock

In stock

WD1745771347

Price

€11.95

In stock

In stock

WD1744021808

Price

€11.95

In stock

In stock

WD1743076631

Price

€31.95

Free shipping!

In stock

WD1737917322

Price

€27.95

Free shipping!

In stock

WD1737917233

Price

€26.95

Free shipping!

In stock

WD1737712187

Price

€34.95

Free shipping!

In stock

WD1736243748

Price

€14.95

In stock

In stock

WD1734610031

Price

€24.95

Free shipping!

In stock

WD1734609834

Price

€24.95

Free shipping!

In stock

WD1734608916

Price

€32.95

Free shipping!

In stock

WD1734608403

Price

€1.75

In stock

In stock

WD1734608282

Price

€1.49

In stock

In stock

WD1733573701

Price

€21.95

Free shipping!

In stock

WD1733573124

Price

€19.95

Free shipping!

In stock

WD1733572812

Price

€29.95

Free shipping!

In stock

WD1733163575

Price

€31.95

Free shipping!

In stock

WD1733163321

Price

€26.95

Free shipping!

In stock

WD1733162693

Price

€26.95

Free shipping!

In stock

WD1732823554

Price

€28.95

Free shipping!

In stock

WD1732791139

Price

€36.95

Free shipping!

In stock

WD1732790741

Price

€23.95

Free shipping!

In stock

WD1732790453

Price

€31.95

Free shipping!

In stock

WD1732789953

Price

€32.95

Free shipping!

In stock

WD1732789298

Price

€35.95

Free shipping!

In stock

WD1729183106

Price

€9.95

In stock

In stock

WD1728303209

Price

€23.95

Free shipping!

In stock

WD1728302946

Price

€24.95

Free shipping!

In stock

WD1728302876

Price

€24.95

Free shipping!

In stock

WD1728302751

Price

€24.95

Free shipping!

In stock

WD1728302684

Price

€23.95

Free shipping!

In stock

WD1728302609

Price

€23.95

Free shipping!

In stock

WD1728302421

Price

€24.95

Free shipping!

In stock